Brand:Hi Now

Product origin:China

Delivery time:25 days

Options: automatic capsule and material feeding, pellet filling station,wet water pump, customized size, customized electrical configuration

Machine parameters

|

Model |

NJP-2500C type |

|

Filling capacity |

150 000 grains/hour |

|

Weight |

1500Kg |

|

Dimension |

1190×1120×2015mm(height with automatic powder feeder: 2600MM) |

|

Power supply |

380/220V 50Hz |

|

Total power |

8KW |

|

Segment bores |

18 holes |

|

Vacuum |

63m 3 /h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m 3 /h |

|

Air compression |

Air consumption 6 m 3 /h Pressure 7-8Kg |

|

Water source |

500L/H 0.2-0.3Mpa |

|

Operating noise |

< 75 DB(A) |

|

Filling percentage |

Empty capsule 99.9% Full capsule 99.8 % |

|

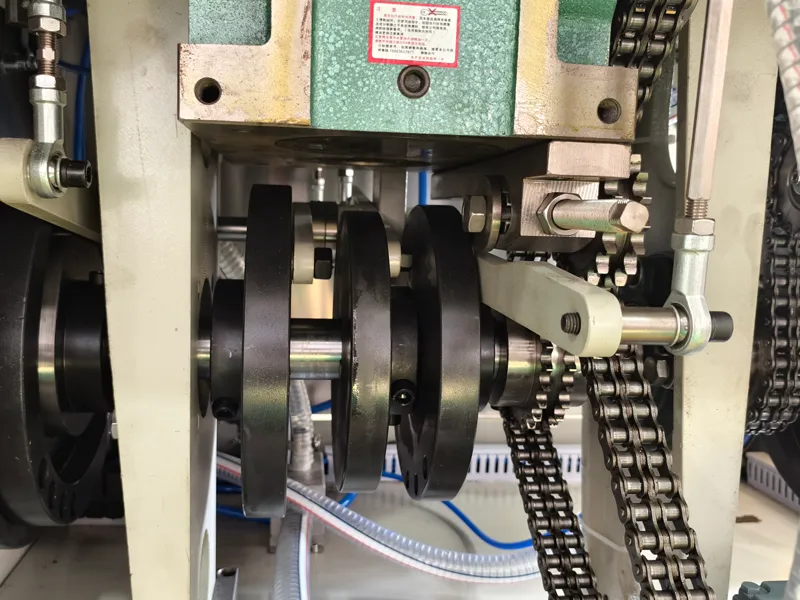

Capsule size |

00.0,1,2,3,4,5# safety capsule AE |

|

Filling accuracy |

Western medicine ± 3% Chinese medicine ± 4% |

|

Suitable for |

powder, granules, pellets, tablets |

NJP-2500C Automatic Capsule Filling Machine

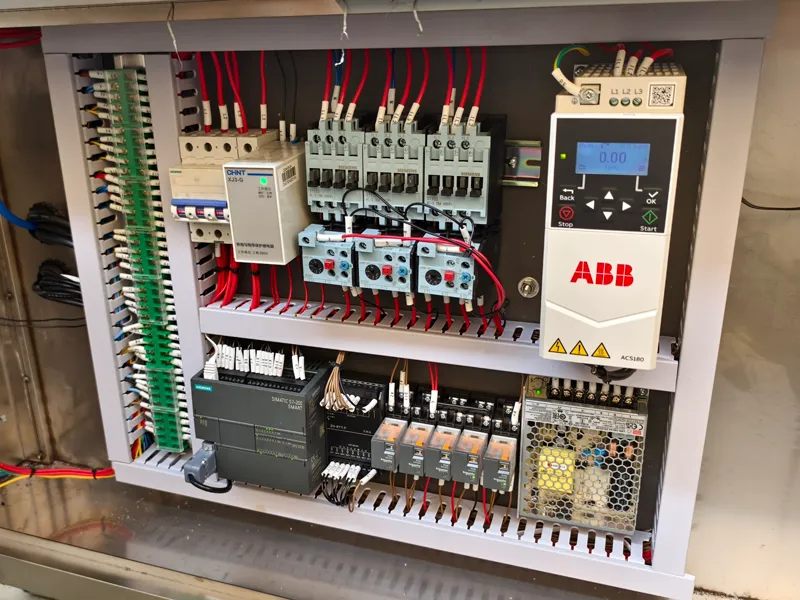

1).This Machine absorbs the advantages of other similar capsule filling machines and is a self-designed and researched advanced empty capsule filling machine.

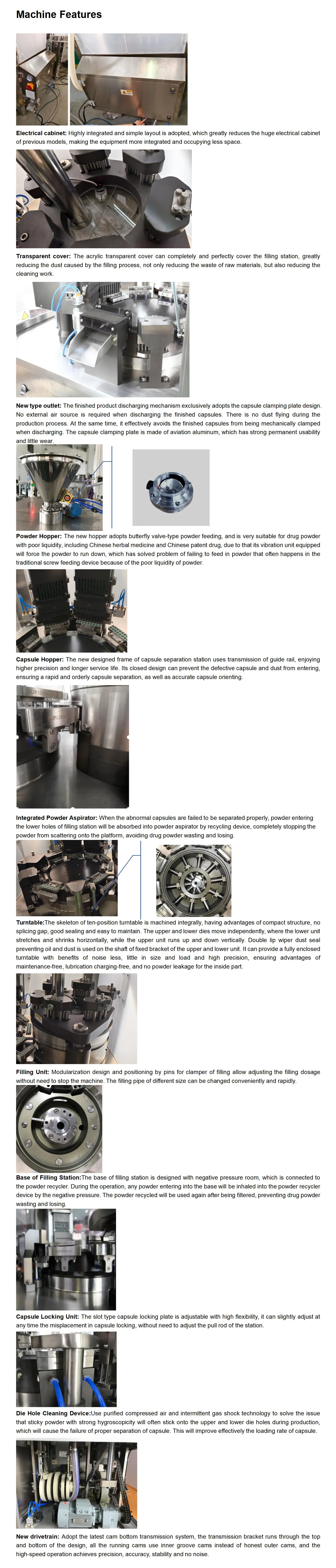

2).Adopt forged surface cam transmission structure and there is nospring in the transmission part.

3).Adopt full closed work station rotating plate with automatic lubricating system.

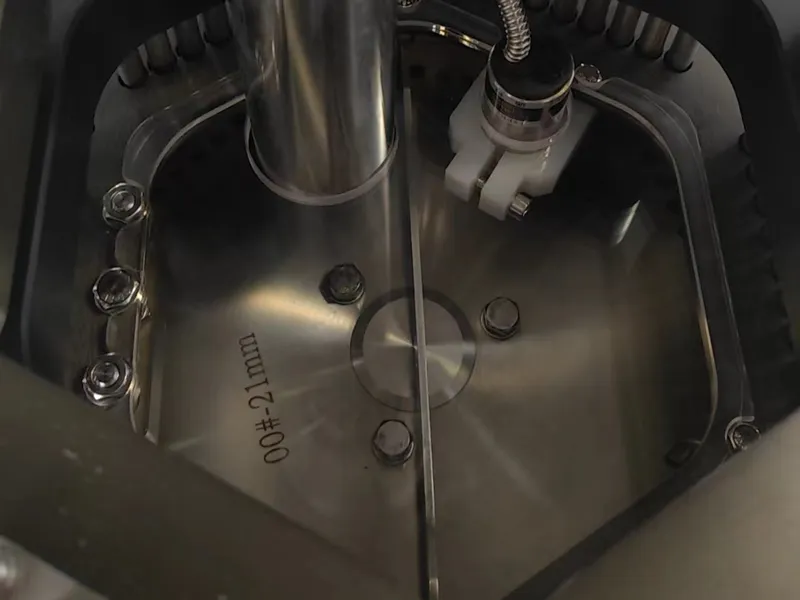

4).Adopt 10.4inch colorful LCD screnn to auto-alarm and auto-stop under the conditions of lacking capsules,lacking prwder,vacuum failure,dust absorption failure or the machine gate loosen.

5).Adopt import main engine,electrical components,bearing and high-precision periodical indexing box(the space between input shaft and output shaft increase from 83MM to 145MM)to increase the stability of control system and drive system.

6).Patented modularized punch holder mechanism and double pitch feed copper to facilitate dismounting and accurate positioning.

7).Machine and electric parts are separated,which is easy to clean and keep safe.

8).This machine has been awarded more than 10 items of Chinese patents.