Brand:Hi Now

Product origin:China

Delivery time:25 days

Options: automatic capsule and material feeding, pellet filling station,wet water pump, customized size, customized electrical configuration

Machine parameters

|

Model |

NJP-7800C |

|

Filling capacity |

468000pcs per hour |

|

Weight |

3500Kg |

|

Dimension |

1880×1390×2400mm |

|

Power supply |

380/220V 50Hz |

|

Total power |

13KW |

|

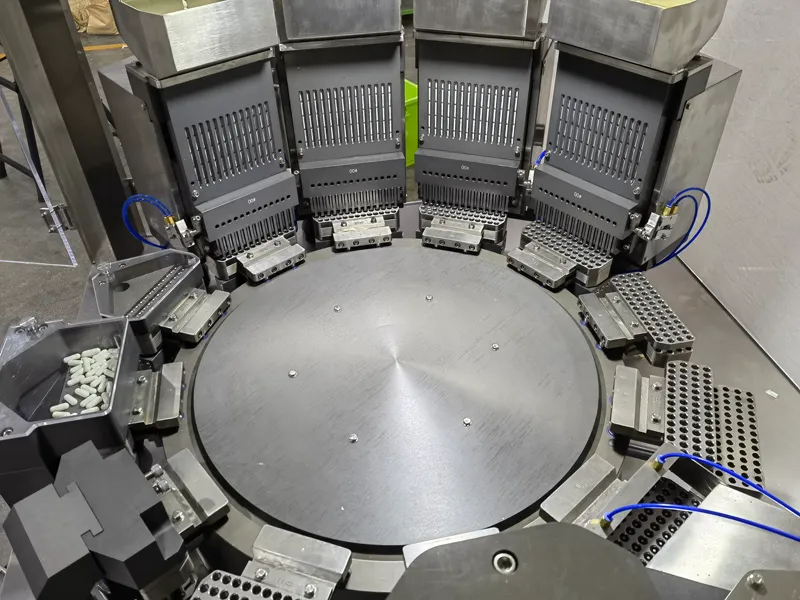

Segment bores |

55 holes |

|

Vacuum |

120m3/h-0.04-0.08Mpa |

|

Dust collector |

24.5Kpa 210m3/h |

|

Air compression |

Air consumption 7m3/h Pressure 7-8Kg |

|

Water source |

1000L/h 0.3-0.4Mpa |

|

Operating noise |

<75DB(A) |

|

Filling percentage |

Empty capsule 99.9% filled capsule 99.8% |

|

Capsule size |

00,0,1,2,3,4,5# |

|

Filling accuracy |

Western medicine ±3% Chinese medicine ±4% |

|

Suitable for |

Powder, Granule, Pellet, Tablet. |

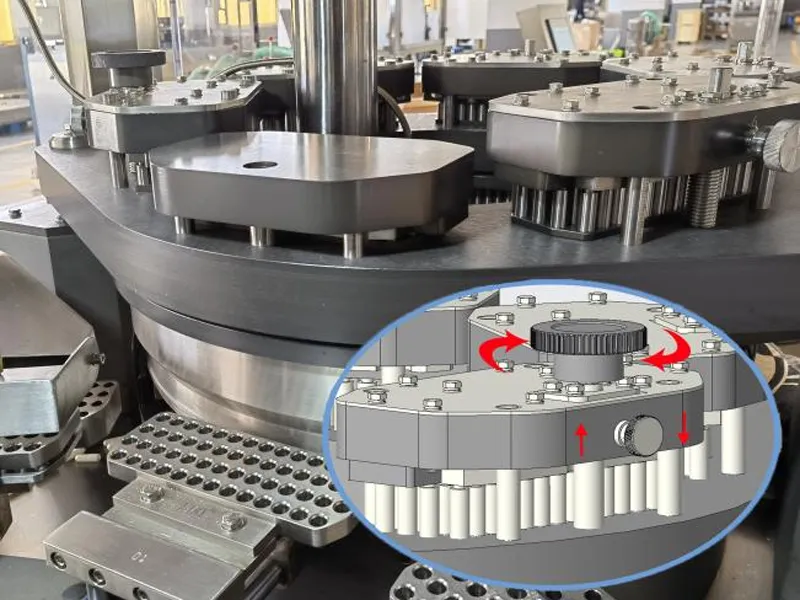

Introduction

The NJP-7800 Automatic Capsule Filling Machine delivers high-speed productivity of 7,800 capsules per minute, ensuring low maintenance, minimal downtime, and reliable operation. It utilizes 5-stage tamping technology for precise powder dosing and supports pellet filling. Capsules from the hopper are fed into the orienting device through a vertical guide, then transferred into dedicated rotor cells. Within the rotor, capsules are separated into body and cap sections, with the body moving to the filling station for material loading. At subsequent stations, non-separated capsules are automatically rejected, while filled bodies are rejoined with caps, counted, and discharged into the collection container. The machine is fully compliant with cGMP and FDA specifications for pharmaceutical-grade production.