Brand:Hi Now

Product origin:China

Delivery time:30 days

Options: automatic tube and material feeding, Heated mixing hopper, customized size, customized electrical configuration

Machine Parameter

Filling volume

1-300ml/unit (Adjustable)

Filling accuracy

≦±0.5﹪

Capacity

3000-4800units/hour (Adjustable)

Tube diameter

Φ10-50 mm

Tube length

210mm (can order)

Hopper volume

40L

Equipped motor

1.1KW

Machine power

2kw

Dimension

22700×960×2100(mm)

Power supply

380/220 (Optional)

Weight

About1200 Kg

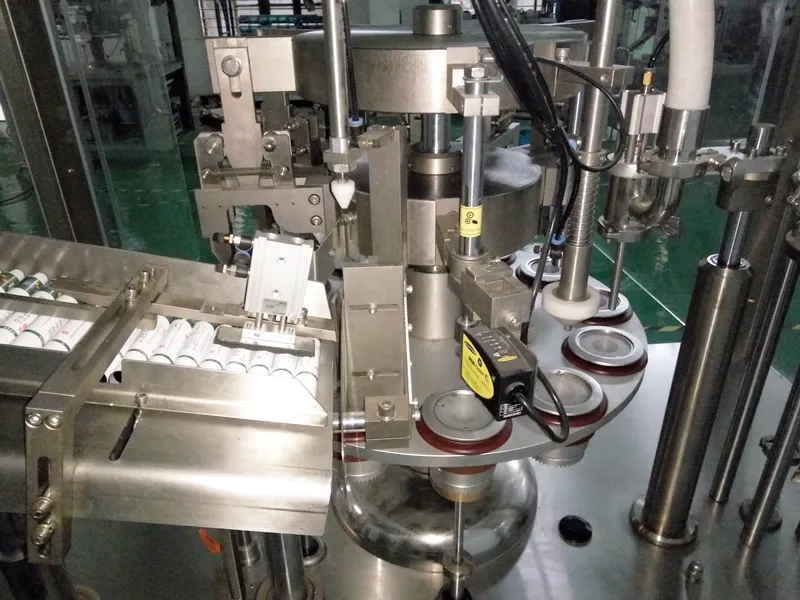

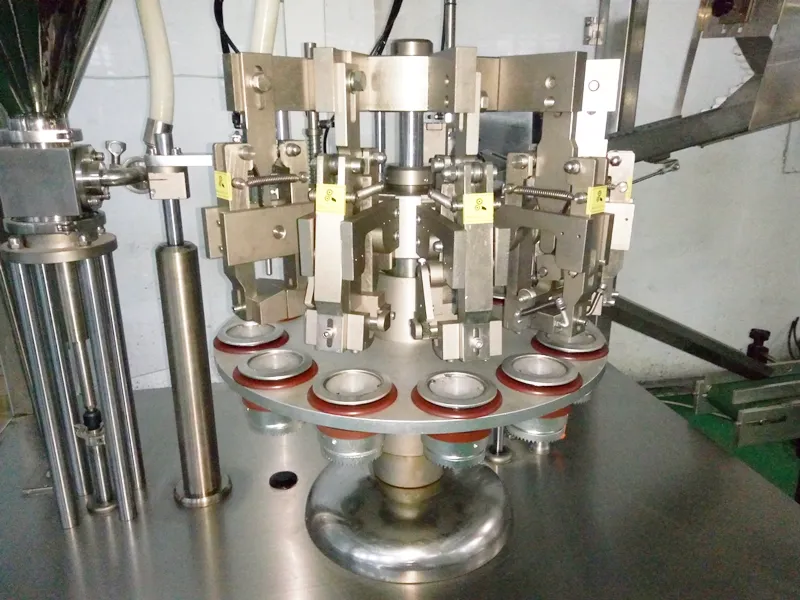

The HNM-80 Automatic Tube Filling & Sealing Machine is a high-tech equipment developed using advanced international technology, fully compliant with GMP standards. Featuring a PLC controller and color touchscreen interface, it enables programmable automation for precise filling of ointments, creams, gels, or viscous materials, followed by sealing/tail folding and automatic batch number embossing (including manufacturing date). This machine is ideal for aluminum tube filling and sealing in cosmetics, food, and adhesives industries.

Key Features

◆Compact Design

◆Driving Parts Fully-closed

◆Pneumatic Tube Washing & Feeding

◆Intelligent Temperature Control and Cooling System

◆Easy to Operate and Adjust

◆316L Stainless Steel Contact Parts to meet GMP Standard

◆Safety Interlock Shutdown when Door is Open

◆Overload Protection Provided

◆Automated Working process from Tube Loading to Finished Products Output

◆Automatic Orientation Effected by Photoelectric Induction