Brand:Hi Now

Product origin:China

Delivery time:25 days

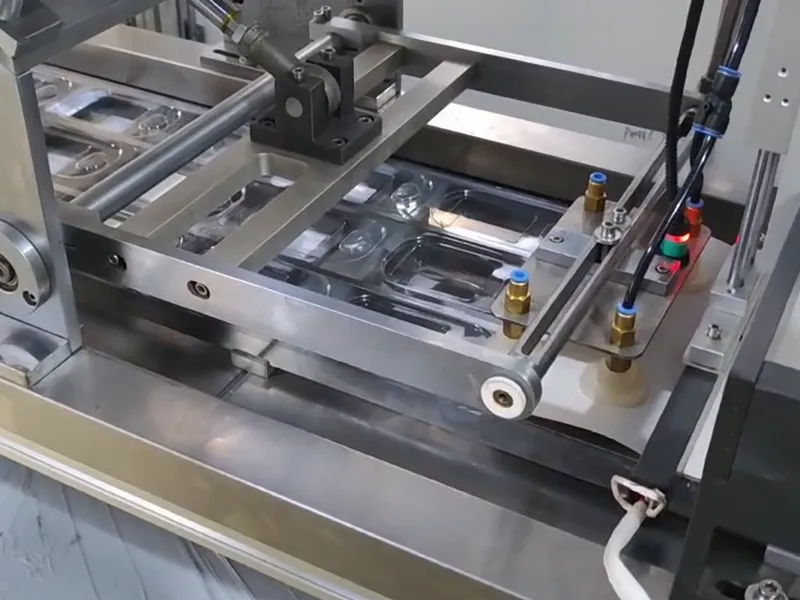

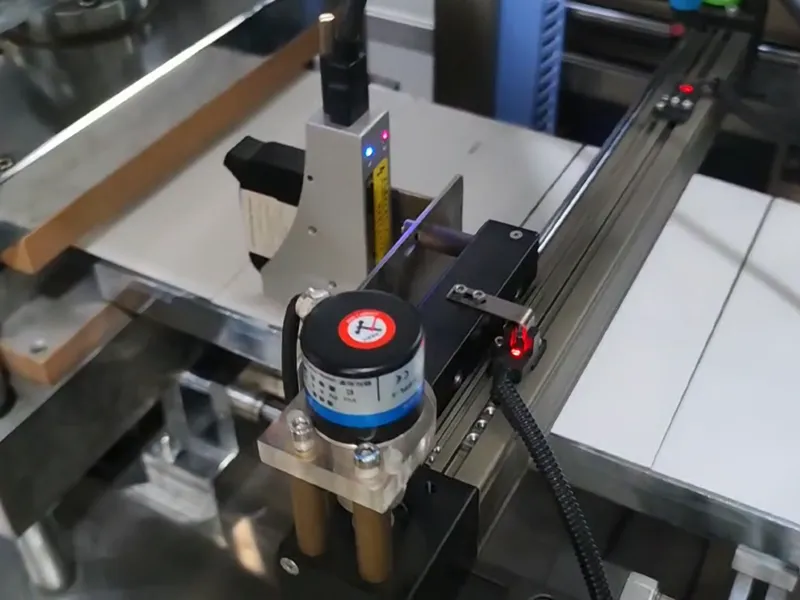

Options: Chiller,Air compressor, online inkjet printer and labeling, Eye mark,customized size, customized electrical configuration

Machine parameters

|

Model |

DZP-260 |

|

Punch Speed |

Production capacity: 10-15 times/min |

|

Materials and specifications |

Paper card: 255mm wide, 0.05-0.10 thick; medical PVC maximum width 260mm, 0.25-0.35mm thick |

|

Stroke range |

35mm - 180mm |

|

Packaging efficiency |

(Depending on the packaging area) |

|

Packaging range |

Suitable for toothbrushes, chopsticks, daily necessities, small hardware, cosmetics, stationery, etc. |

|

The main function |

Adjustable stroke device Mould plate positioning device Plate heating device Servo traction Finished product punching output |

|

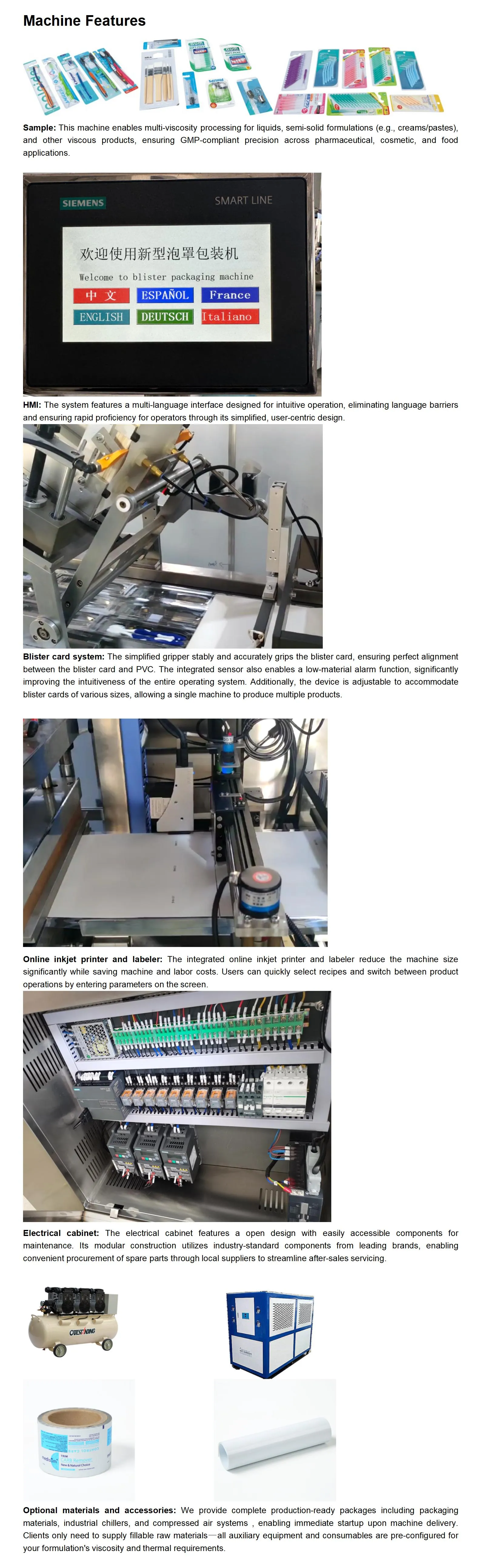

Maximum forming depth (mm) |

28mm |

|

Maximum molding area (mm 2 ) |

250×170×28mm |

|

Power Specifications |

Three-phase 380V 50Hz-60Hz |

|

Total power consumption (kW) |

10KW |

|

Compressed air pressure (MPa) |

0.6-0.8MPa |

|

Compressed air consumption (m 3 /h) |

≥1m 3 /min |

|

Cooling water consumption (m 3 /h) |

Refrigeration cycle cooling water |

|

Noise(dB) |

60-70dB |

|

Overall dimensions (L×W×Hmm) |

4300×800×1650mm |

|

Weight (kg) |

1500kg |

Introduction

Form-fill-seal blister machine for toothbrushes and other small brushware. Throughput is maximized by forming multiple blisters in one sheet and separating individual packages at the final cutting station. The blisters are punched out by matched-metal dies for a superior quality cut.