Brand:Hi Now

Product origin:China

Delivery time:25 days

Options: Chiller,Air compressor, variable inkjet printer, Eye mark,customized size, customized electrical configuration

Machine parameters

Punches frequency

10-35times/min

Production capacity

1200-4200 bisters/hour

Max. forming area and depth

150x110(standard thickness≤15mm) Max. depth 26mm

Stroke range

50-120mm( can be designed as per user’s required)

Standard plate size

80x57mm ( can be designed as per user’s required)

Clean compressed air

0.4∽0.6Mpa

Air compressed capacity

≥0.3m3/min

Total power supply

380V 50HZ 3.8kw

Main power

1.5KW

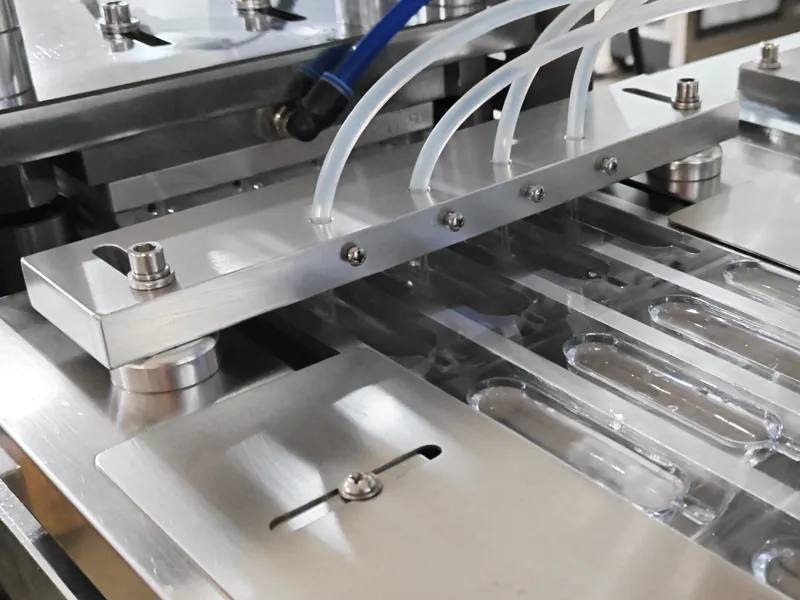

PVC hard film

(0.15∽0.5)×150mm

PTP Aluminum film

(0.02∽0.035)×150mm

Dialysis paper

(0.02∽0.035)×150mm

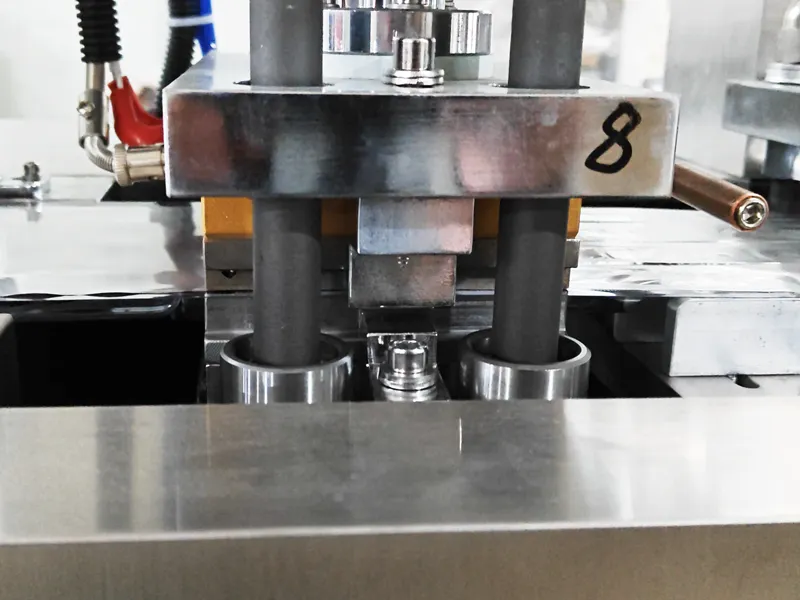

Mould cooling

Tap water or recycling water

Overall dimension

2315×635×1405mm(L×W×H)

Net Weight

820KG

Noisey Noise

<75dB

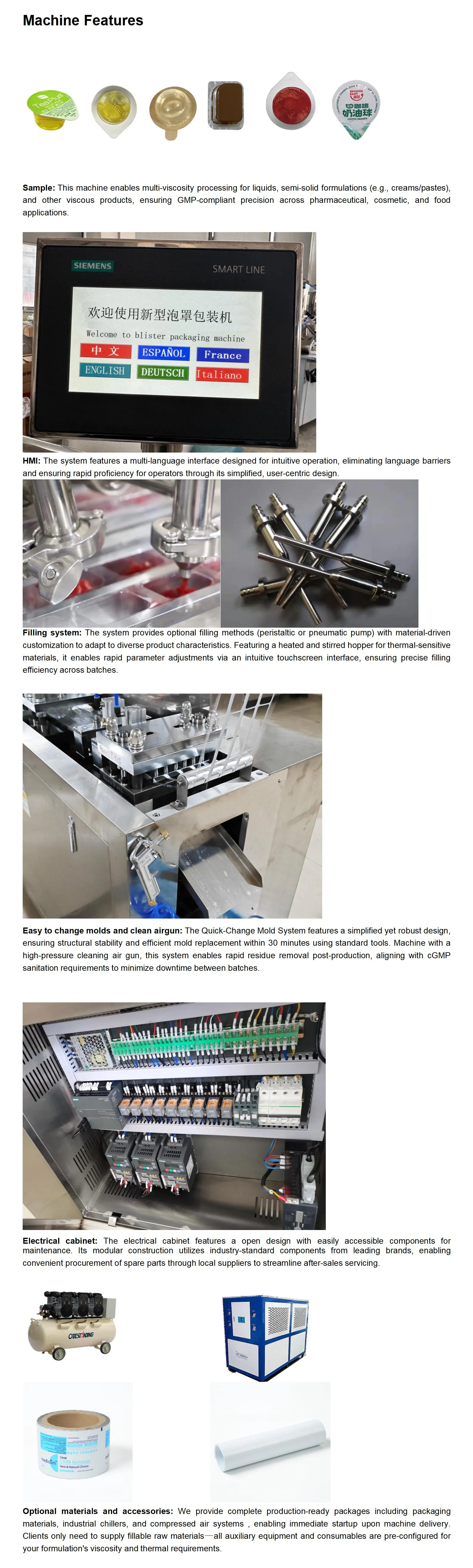

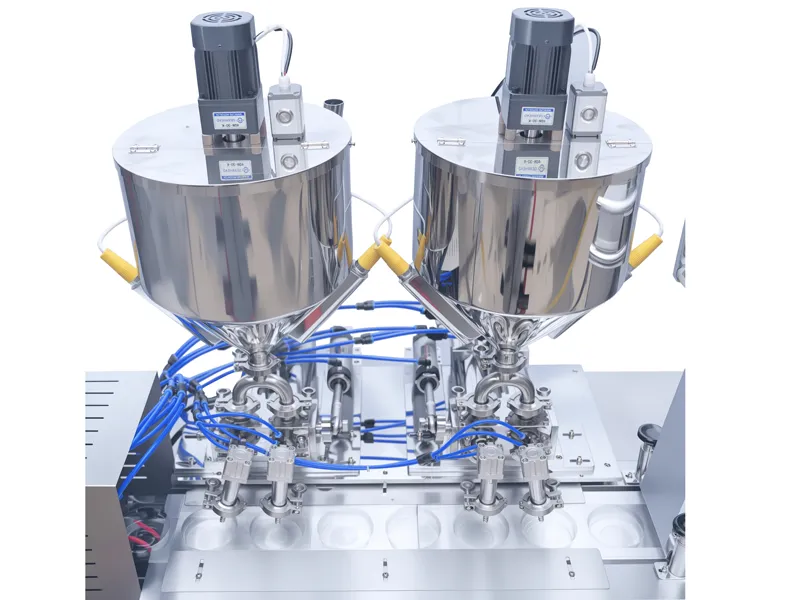

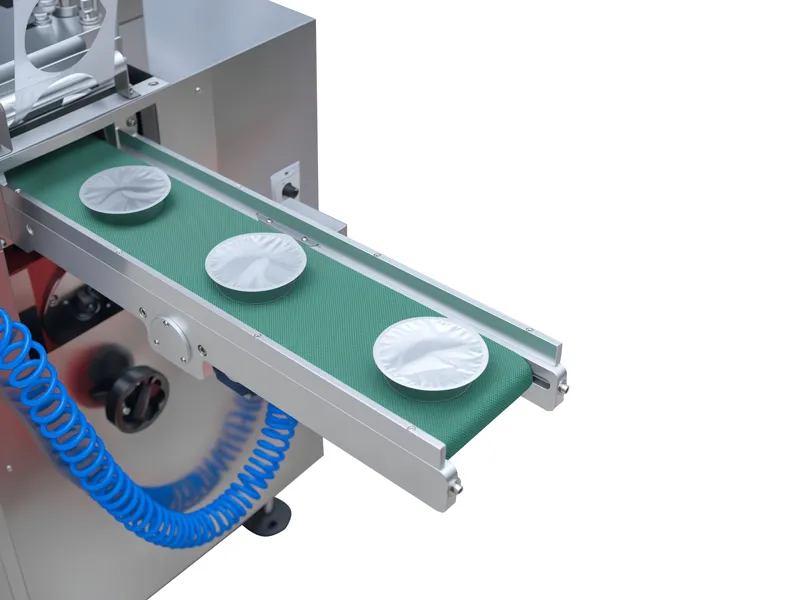

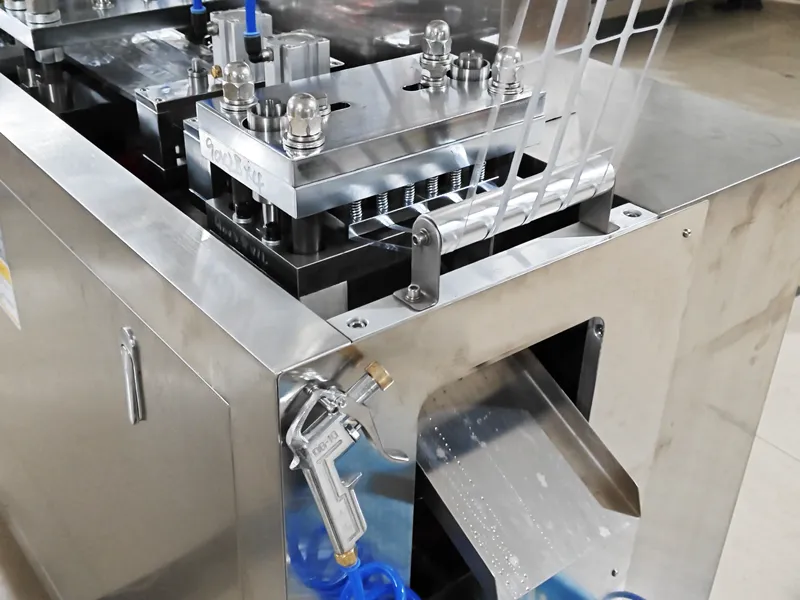

The DPP-150 utilizes a flat-heat plate system to uniformly warm PVC sheets to 105°C±2°C, enabling precise cavity forming via positive pressure. This all-in-one machine seamlessly executes heat sealing, batch coding, creasing, automated slicing, and auto-stop alerts with PLC-controlled accuracy. Featuring stepless speed regulation (10-35 cycles/min), its spiral rod drive allows on-the-fly adjustments to sheet dimensions, while the pneumatic roller traction system ensures stable material feeding with customizable stroke lengths (50-120mm). Designed for versatility, it supports rapid format changes for diverse blister sizes and integrates servo-driven components to minimize alignment errors (±0.3mm). Ideal for small-to-medium batches, the DPP-150 combines low-maintenance operation with energy-efficient heating and tool-free cleaning access, reducing downtime by 40%. Compact yet industrial-grade, it meets ISO 9001 standards for pharmaceutical tablets, food supplements, or viscous product packaging.