Brand:Hi Now

Product origin:China

Delivery time:25 days

Options: Chiller,Air compressor, variable inkjet printer, Eye mark,customized size, customized electrical configuration

Machine parameters

Model

DPP-80

Punch frequency

10-33times/min

Production capacity

1980plates/hour

Max. Forming area & Depth

105x70(standard depth ≦15mm), Max. Depth 25mm( As adjusted

Standard Stroke range

30-80mm(can be designed as per user’s required)

Standard plate size

80x57mm (can be designed as per user’s required)

Air pressure

0.4-0.6Mpa

Compressed air required

Air compressor≥0.3m3/min

Total power supply

220V 50Hz 2.4Kw

Main motor

0.75Kw

PVC hard Film

0.15-0.5*110 (mm)

PTP Aluminum film

0.02-0.035*110 (mm)

Dialysis Paper

50-100g*110(mm)

Mould cooling

Tap water or Recycling water

Overall Dimension

1840x590x1100 (mm)(LxWxH)

Weight

Net 415kg Gross weight: 465kg

Noise index

<75dBA

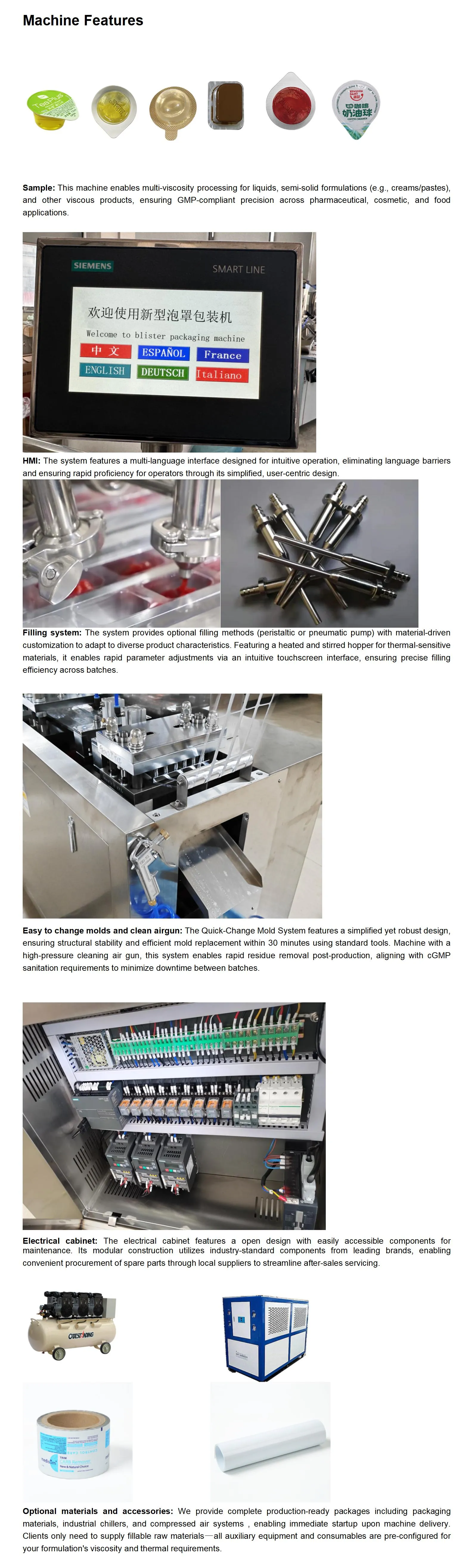

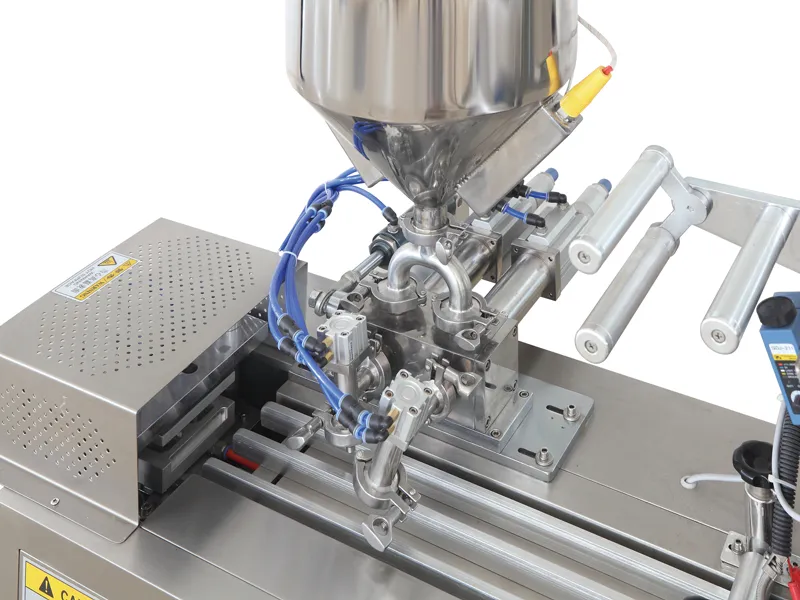

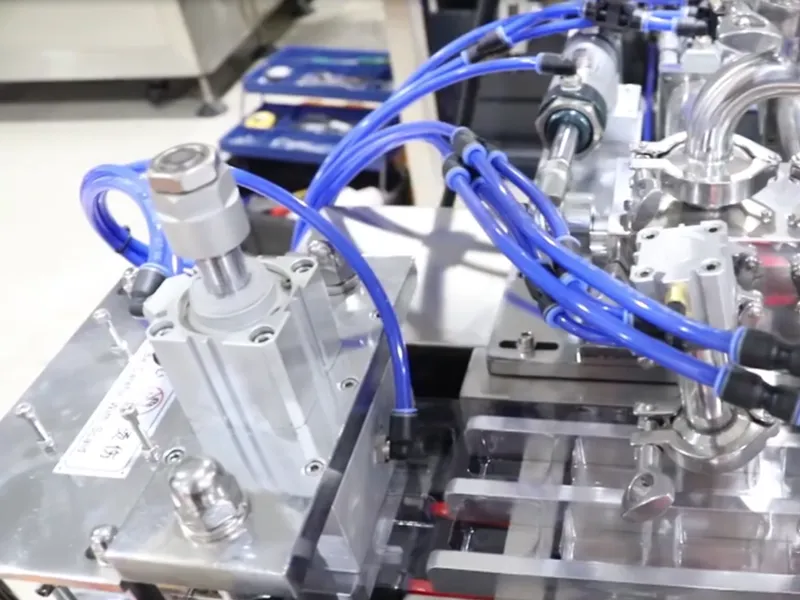

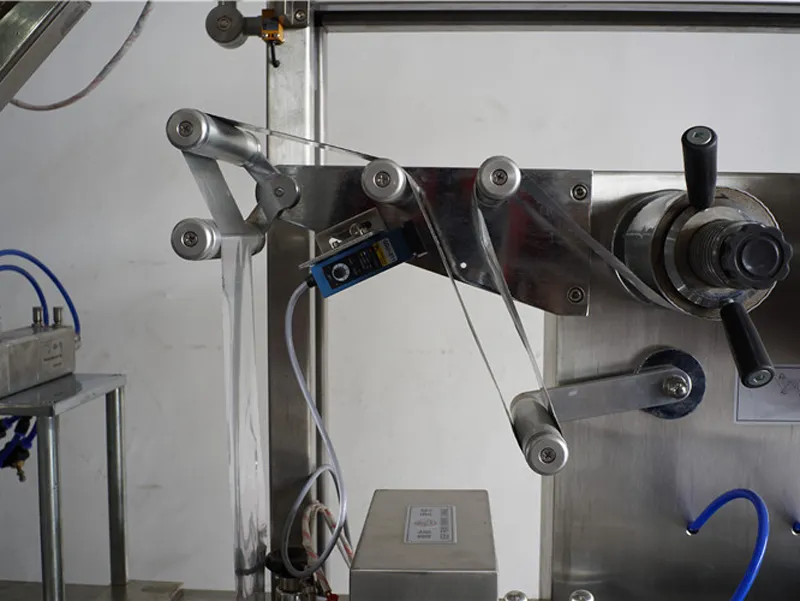

Introduction

The Chain-Driven Precision Packaging Machine integrates an innovative domestic chain transmission system to eliminate gear-induced positioning errors and reduce noise (<70dB). Equipped with EU-certified PLC controls and a stainless steel frame, it supports modular upgrades: automatic material compensation,and high-resolution inkjet printing. The photoelectric synchronization system ensures alignment for multi-station PVC/PTP/hard aluminum packaging, paired with auto waste trimming. Designed for small-batch flexibility, its pneumatic-driven operation and intuitive touchscreen interface enable effortless control—even for blister packaging novices—while minimizing maintenance costs. Compact and GMP-ready, this machine optimizes chocolate, sauce, or pharmaceutical packaging with stepper motor traction and laser-guided correction. Ideal for SMEs seeking cost-effective scalability, it combines industrial durability with plug-and-play simplicity to boost production efficiency in space-constrained facilities.